Stainless steel beer conical fermenter for beer plant and factory

Product Description

ZH- craft beer brewing equipment

Applications area: Beer Bars, Hotels, Restaurants etc.

Product features:

1. Appearance clean and generous: The tank is polished by mirror, and the equipment is bright;

2. Good insulation effect: The equipment is divided into two kinds of heat insulation and cold insulation, which is the best to ensure the temperature of the beer brewing process;

3. Visualization operation: the equipment is controlled by PLC, and the fermentation tank is equipped with a glass tube level gauge, which is convenient for visual operation;

4. Low energy consumption: environmental protection, energy saving, low power consumption, saving energy consumption of about 20%;

|

1

|

malt milling system

|

malt miller machine

grist case

|

|

2

|

Mash system

|

Mash tank/lauter tank

Boiling tank/whirlpool tank

Hot water tank

Mash/wort/hot water pump Motors

Wort oxygenation device

Operation platform

Plate heat exchanger

|

|

3

|

Fermenting system

|

Beer fermenters

Bright beer tanks

Yeast adding tank

Accessories, such as sample valve, pressure gauge, safety valve and so on

|

|

4

|

Cooling system

|

Ice water tank

Refrigerating unit

Ice water pump

|

|

5

|

CIP cleaning system

|

disinfection tank & alkali tank &cleaning pump etc.

|

|

6

|

Controller

|

Control system, we have PLC automatic and semi-automatic, the elements brand include LG, Siemens and so on.

|

|

7

|

Kegging system

|

kegging system ( keg washer and keg filler machine), the control system brand is Siemens.

|

Detailed Images

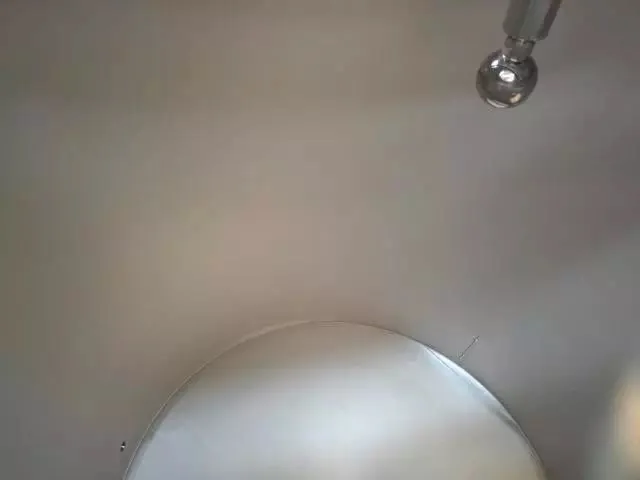

Fermentation system:

1.The inner of the fermentation tank are adopted 304 stainless steel. Use polyurethane to keep warm. The outside scarfskin is according to the customer’s requirement.You can choose stainless steel polishing, carbon steel, spray finishing and so on.

2.Adopted the international standard of fermentation technology, diverse methods to control the temperature. The inner surface of the tank is mirror-polished. The standard is≤0.8um ≤0.6um ≤0.2um. Completely meet the demand of PLC and sterilize system.

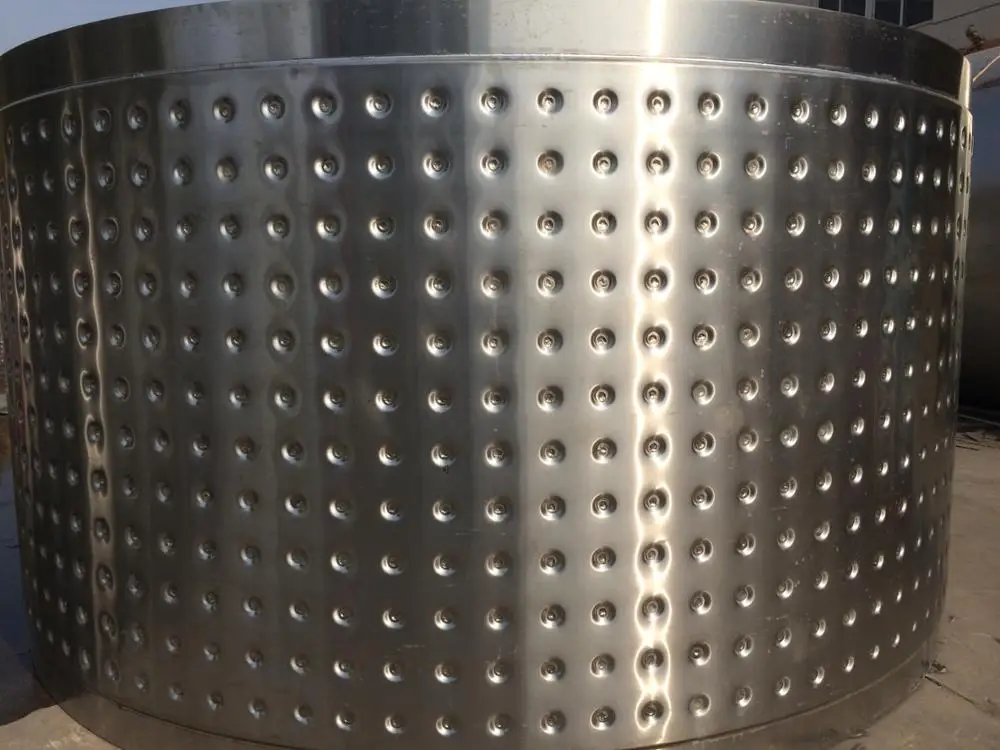

3.The cooling jacket can achieve all countries’ standard, supply Miller, arch, corrugated plate and so on. Meet all kinds of demand of cooling technology of coolant and pressure.

Internal pickling passivation finish 0.4 microns

Cooling jacket plate

Valve Other Accessories

Production Process

Production strength: with 12,000 square meters of production area, own shearing machine, bending machine, large multi-polishing machine, pressing machine, plasma cutting machines and other processing equipment more than 30 pcs; has two high-standard production lines, all kinds of and senior technicians more than 60 people; with advanced beer, wine processing technology.

Our Services

Service system: Zunhuang has professional service team to ensure can solve the problem within 48 hours for customers in domestic. At the international service, Zunhuang Company has been set up regional agency and the perfect service organization in Slovakia, Russia, Spain and Italy in Europe, North America and Canada, Brazil, Australia , Japan and India.

Ten provide to service you

1. After-sale Service for the whole life.

2. 24h service for you, solve your urgent problem first time.

3. 3 years warranty for the main products.

4. Free design for your brewery layout for 2D or 3D.

5. Spare parts replacement and repair service provided.

6.Engineer going abroad for installation, debugging and technical training if you need

7. Provide the Form E, CO, etc..others necessary reduce import Tax files for you.

8.To provide update information about brewing equipment technology once we test.

9.Help you send the goods if you have others company order, then send to you together.

10. Door to Door service, if you need any brewing parts.

Company Information

Shandong Zunhuang Brewing Equipment Co., Ltd is the domestic integrated industrial and tradecomprehensive enterprise dedicated in research, manufacturer, development, sales and after-sale service, until now have the 16 years produce experience, company focuses on beer system project that refer to fruit wine equipment, white spirit and alcohol equipment etc, corollary equipment, our company purpose: “Quality first, customer highest”, use the short period provide direct and comprehensive service, and improve the products’ valve and market competitive.

FAQ

FAQ:

1.Q: Are you a manufacturer?

A: We are the manufacturer of beer brewing equipment for 16 years.

2.Q:Can I have the customized products for myself?

A:Yes,we can design and manufacture as client's requirements.

3.Q: Can you guarantee your quality?

A: All of our products is applied with CE certificate and highly in accordance with GMP. Equipment is made of high quality of SUS304/316. Inspect certificate is available.Also we support you inspecting our equipment abefore delivery or sign the contract.

4.Q:How about the after sales service?

A:For our after-sale service, we promise all life of technical support to new and old customers.

All of our products is available with 10 years warranty even for spare parts within quality warranty period, our service is free of charge.

Contact info

Pls feel free to contact us if you interested in beer brewing equipment. Cheers!!